The history of the iron industry and the growth of Maryland during the industrial revolution are closely tied. As iron mining and smelting spread from Europe to the colonies, new industrial towns and supporting industries grew up around the mines, smelting furnaces and foundries. In Maryland, these growth trends matched the Arundel Ore belt, which follows the demarcation between Maryland’s coastal lowlands and its Piedmont Plateau and consists of primarily bog iron ore.

The history of the iron industry and the growth of Maryland during the industrial revolution are closely tied. As iron mining and smelting spread from Europe to the colonies, new industrial towns and supporting industries grew up around the mines, smelting furnaces and foundries. In Maryland, these growth trends matched the Arundel Ore belt, which follows the demarcation between Maryland’s coastal lowlands and its Piedmont Plateau and consists of primarily bog iron ore.

Once the bog iron ore was extracted from the ground, it was smelted or melted to produce metal. The early method of smelting in Maryland was what is known as bloom smelting, which used a small forge with a single air blast nozzle known as a tuyere. The tuyere’s air blasts drove a charcoal-fueled fire to form a mass of relatively pure iron and waste, or slag. That was further forged into wrought iron.

Bloom smelting could only be done on a small scale. At the end of the 18th century, advancements in iron smelting led to the development of the blast furnace and blast smelting. While this method could only produce cast, not wrought iron, it could run for months at a time, as opposed to bloom smelting, which could only run for a few days. A process was developed that could convert cast iron to wrought iron. The Catoctin Furnace in Cunningham Falls State Park is an example of a blast furnace, as was the Elkridge Furnace.

Bloom smelting could only be done on a small scale. At the end of the 18th century, advancements in iron smelting led to the development of the blast furnace and blast smelting. While this method could only produce cast, not wrought iron, it could run for months at a time, as opposed to bloom smelting, which could only run for a few days. A process was developed that could convert cast iron to wrought iron. The Catoctin Furnace in Cunningham Falls State Park is an example of a blast furnace, as was the Elkridge Furnace.

Whose Forge Was It?

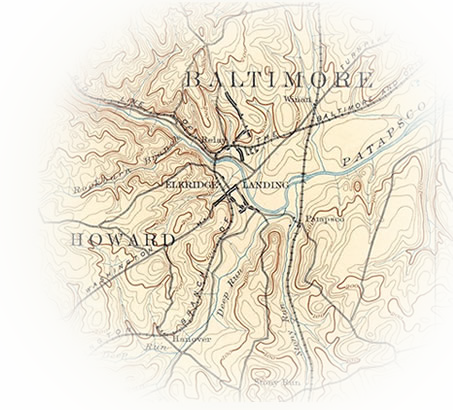

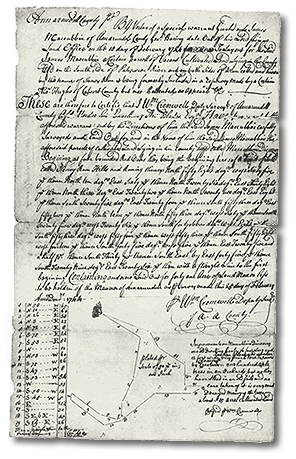

The site is located on a property historically known as “Stoney Run Hills,” which dates to 1724 and was first occupied by Thomas Hughes. In 1744, the property was described as being on the “south side of Patapsco River and on the mouth of a run called Stoney Run…” with improvements consisting of “…one 16 foot square house standing over a water mill with a small shed to one end thereof and a chimney in it.” This description could refer to an early sawmill, small bloomery, or a gristmill. The property was originally 50 acres but was enlarged to 118 acres in 1731.

The site is located on a property historically known as “Stoney Run Hills,” which dates to 1724 and was first occupied by Thomas Hughes. In 1744, the property was described as being on the “south side of Patapsco River and on the mouth of a run called Stoney Run…” with improvements consisting of “…one 16 foot square house standing over a water mill with a small shed to one end thereof and a chimney in it.” This description could refer to an early sawmill, small bloomery, or a gristmill. The property was originally 50 acres but was enlarged to 118 acres in 1731.

James MacCubbin (also McCaubbin) began patenting property in the vicinity of the site in the 1740s. Dr. James Walker, a surgeon and merchant from Scotland who had a store at Elkridge Landing on the Patapsco as early as 1748 (and who conceived the idea for the Elkridge Furnace), consolidated MacCubbin’s parcels, as well as other adjacent tracts, including “Stoney Run Hills”, to form Walker’s Inheritance in 1757. When he died in 1759 his property was divided between his heirs and his business partner, Thomas Harrison, a land speculator who was involved in the development of Baltimore City.

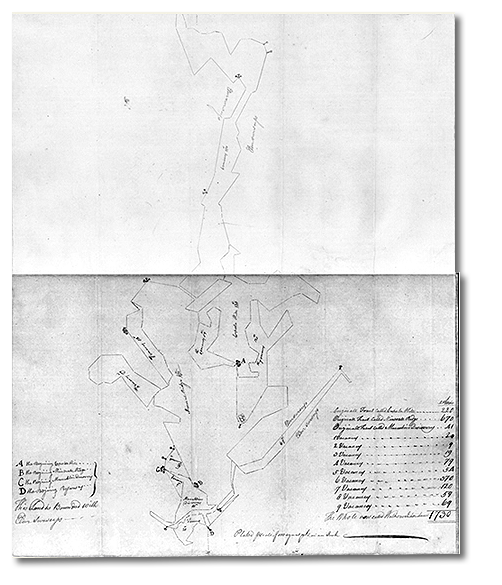

The recently discovered iron forge was likely associated with the furnace complex planned by Walker and Harrison. The complex eventually included two mills, the iron works and multiple millraces from Stony Run and its tributaries. In 1764, the daughters of Thomas Hughes sold the outstanding portion of “Stoney Run Hills” to the heirs of Walker and Harrison. It appears that they derived an income from the property. There was a water mill on the property as early as 1724 and profit may have come from milling operations. Alternatively, the income may have been derived from the presence of ore-rich deposits on the property.

In 1764, the daughters of Thomas Hughes sold the outstanding portion of “Stoney Run Hills” to the heirs of Walker and Harrison. It appears that they derived an income from the property. There was a water mill on the property as early as 1724 and profit may have come from milling operations. Alternatively, the income may have been derived from the presence of ore-rich deposits on the property.

By 1788, Walkers Inheritance and “Stoney Run Hills” had been reorganized and subdivided, passing out of the Walker and Harrison families to Samuel Owings (1788) and then to Jeremiah Yellott (date unknown). Yellott was a merchant from Baltimore who was among the largest ship owners in Baltimore during the last decade of the 18th century. He milled flour, sold it, and transported it via his ships, making him a wealthy man.

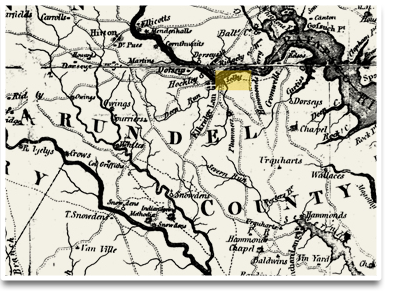

By 1791, Yellott sold a share to his business partner Ennion Williams. The conveyance noted, among other specifications, “two hundred acres of land with the dwelling house, gristmill and other buildings thereon,” marking the second record of a mill on “Stoney Run Hills”, the first being Thomas Hughes in 1724. The remains of the forge or refining furnace were part of a complex containing millraces, a millpond, structures and a gristmill that dates to at least 1791 but likely replaced an earlier mill in the immediate area. The mill, known as Selby’s Mill, appears on the 1794 Griffith Map of Maryland and was located on part of Walker’s Inheritance.

After his death in 1805, Williams and other shareholders fought over the Walker’s Inheritance properties with Yellott’s heirs. By 1808, Ennion Williams mortgaged his property to the shareholders, Francis Hollingsworth and Charles Worthington, selling it to them in 1818. During this period, mills and other industrial operations were becoming more mechanized, requiring investment in new equipment. It would appear these gentlemen were involved in a business arrangement that likely backed the furnace and milling operations. Trade in flour expanded to the West Indies and South America, making Baltimore the country’s largest flour exporter from 1815 through the 1820’s. Perhaps iron from the forge was used to make barrel hoops to containerize the flour from the mill.

Through the mid-1800s, the property remained in private hands, with some modifications made. In 1869, for example, the Baltimore & Potomac (B&P) Railroad Company traversed the property with its rail lines, which necessitated diverting the run from the rail line. The B&P Railroad purchased additional right of way easements in 1892 and in 1908, the latter for a railroad bridge.

In the 20th century, the property changed hands several more times, finally being sold to the Arundel Corporation in 1935. Six owners in the vicinity also sold their property to the Arundel Corporation between 1935 and 1939. In 1979, the Arundel Corporation sold the accumulated properties to the Maryland Department of Natural Resources as an addition to the Patapsco Valley State Park.

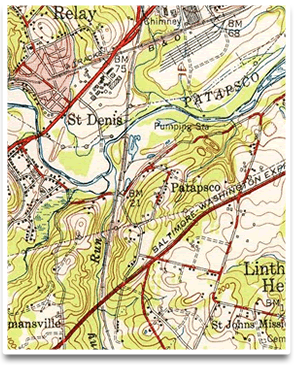

It is unclear how long the forge and mills on the “Stoney Run Hills” property were in operation. Both buildings appear on the 1891 USGS topographic quadrangle. Both buildings are gone by 1947. Records suggest there was a mill in the vicinity as early as the 1720s. The legal battles over the property suggest a value that reflects the operation of the furnace. Records indicate that two mills were in operation in the late 18th century and throughout most of the 19th century. The early 20th century saw subdivision patterns consistent with residential occupation, likely indicating the end of industrial use.

It is unclear how long the forge and mills on the “Stoney Run Hills” property were in operation. Both buildings appear on the 1891 USGS topographic quadrangle. Both buildings are gone by 1947. Records suggest there was a mill in the vicinity as early as the 1720s. The legal battles over the property suggest a value that reflects the operation of the furnace. Records indicate that two mills were in operation in the late 18th century and throughout most of the 19th century. The early 20th century saw subdivision patterns consistent with residential occupation, likely indicating the end of industrial use.